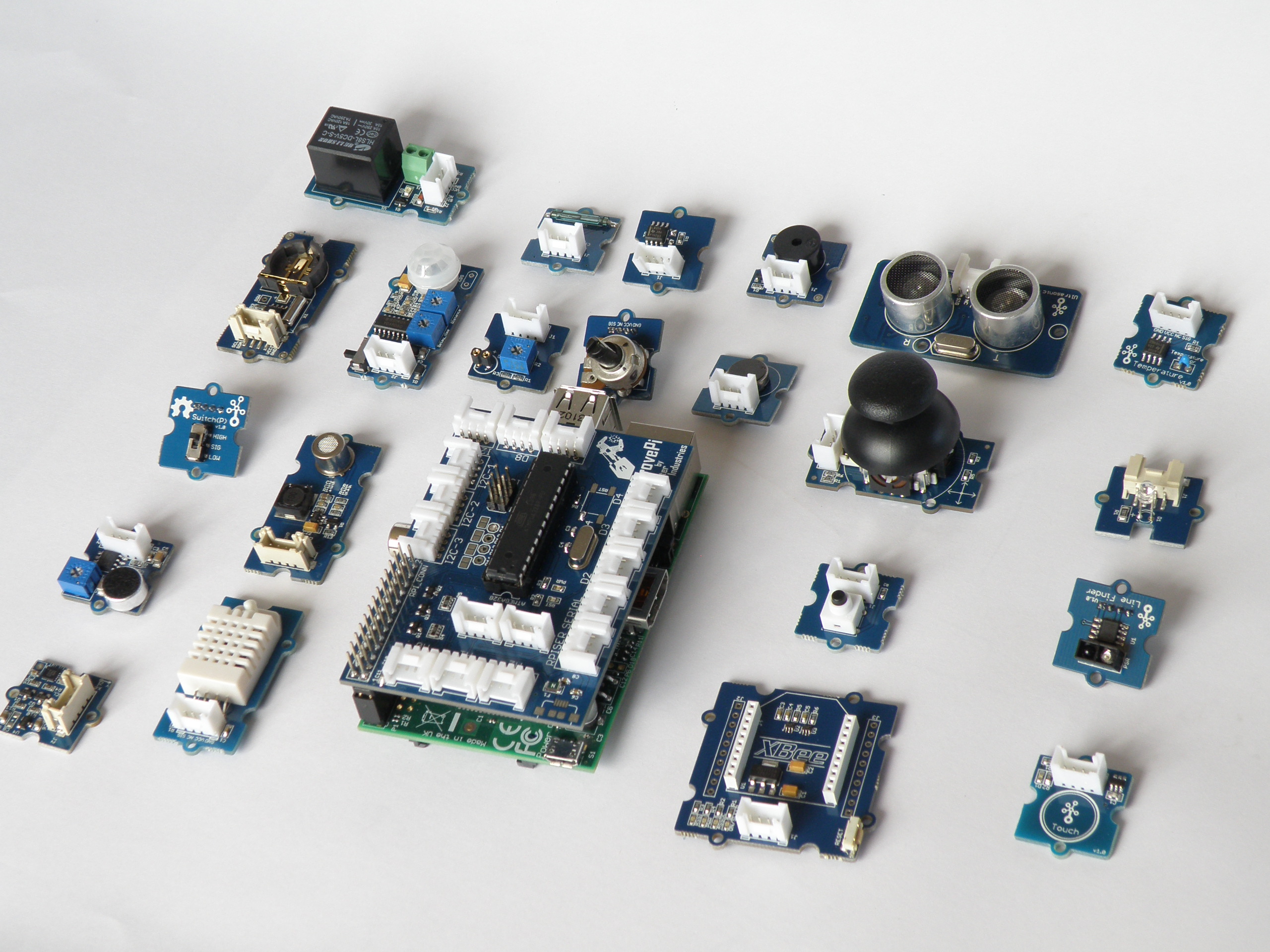

I hate being hostage to proprietary connectors. The way I solve the problem is that, whenever I buy something with grove connectors, I leverage off the connector housing leaving the pins soldered in place, then I pull the pins out of a JST housing and push the JST housing onto the original grove connector pins. No more compatibility hassles.

I totally agree about disliking proprietary connectors, I always use connectors which I can dual source. I’m currently using a Molex housing 22-01-2041 with terminals 0008500113 which I buy on a roll. Probably interchangeable with the JST you use. I selected these as I have access to an Applicator and Press which can cut and strip wires and crimp the terminal.

The purpose of grove connectors on sensor boards, is just to diffentiate between ‘normal’ JST connectors, So you don’t , by mistake , mix them and see some magic smoke.

Main use of course are dev boards and easy interchangeable modules, because the connections (I2C) are all the same.

For industrial mass production its probably cheaper to use non grove connectors, for easy dev and education its a perfect , non soldering , system imho.

From a random search on the web

Thread Size M3-0.5

Thread Type Metric Coarse

Specification Met Din 934

Width 5.5 millimeters

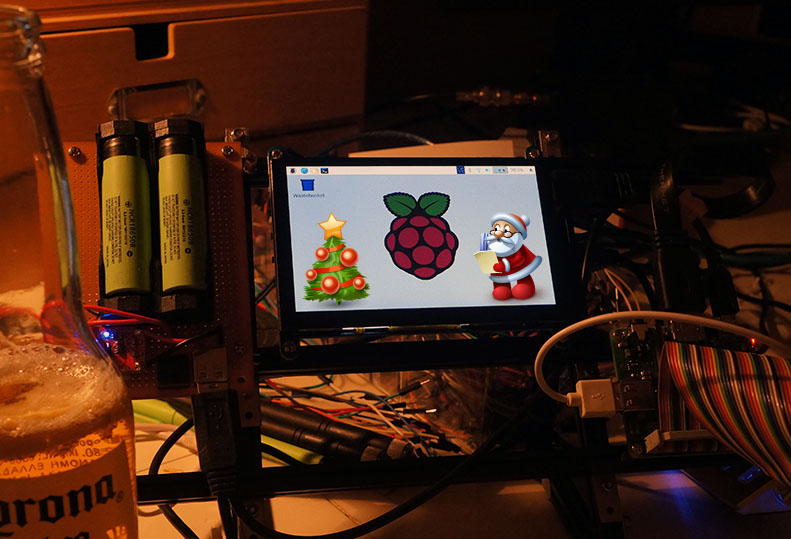

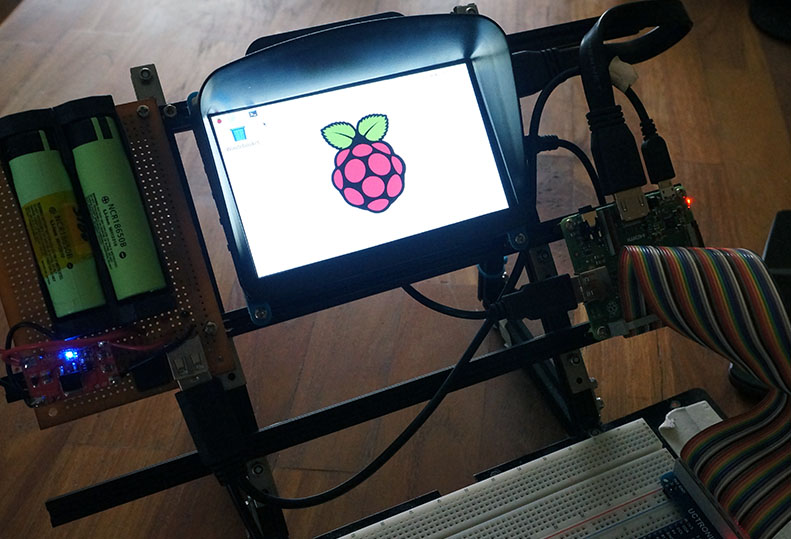

tip for 5 inch Elecrow 800x480 hdmi screen users … this 'sunglare shade thing ’ fits… perfect, glue on the enclosure for use outdoors

@BoRRoZ you have that bottle of “Corona” brand flux a long time. Even still, I guess if it keeps the creativity flowing then it is working…

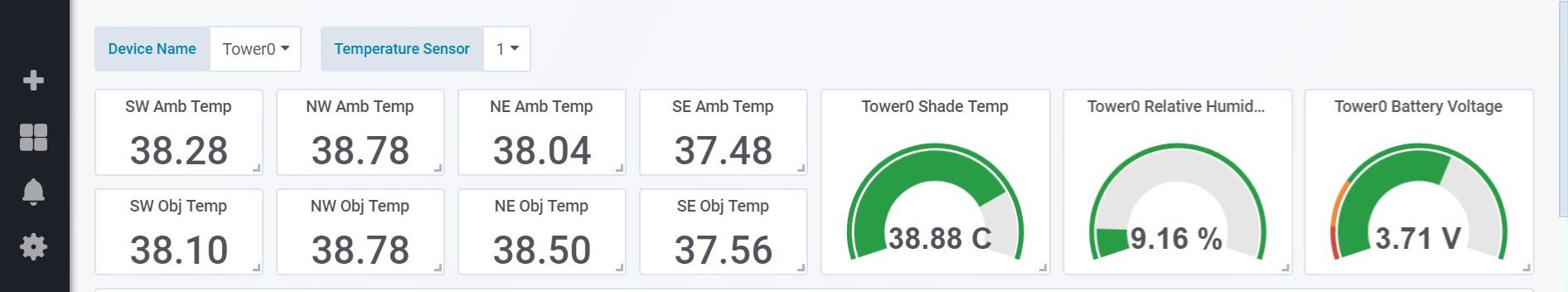

How do you calibrate temperature sensors?

I need a temperature reference of 40C to calibrate some sensors. I could use an exotic temperature controlled heated chamber, but why waste my time and money when I can just go OUTSIDE as it was 41.5C today.

BTW, the fridge is almost empty

I wonder… that high temps. does that have any impact on how you construct LoRaWAN sensors ?

enclosuse… cooiing… electronics in general

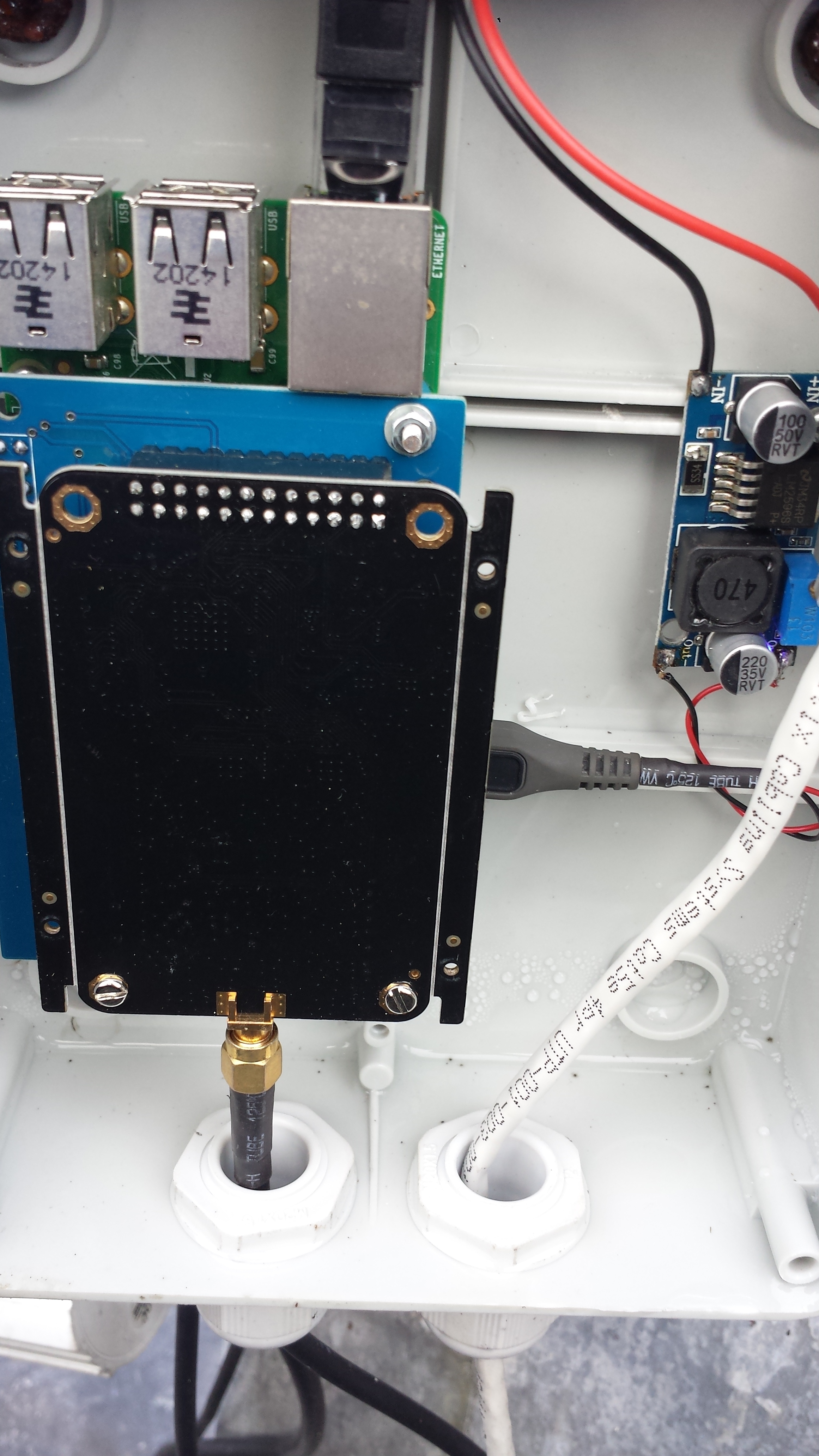

Oh yes, everything needs to be shaded. Nodes in the middle of a field need enclosures that include their own shade. My gateways are self contained and installed in full sun heat transfer becomes the number 1 design issue. With SX1301 chips running so hot by themselves, it becomes a challenge to keep them within temperature limits.

tnx… next time in the field and if allowed/possible take some pictures… love to see how it’s done

climate is changing so even here in Holland we can reach that temp one day

Will do. Also (re)designing gateway (Rev 3) one more time to further reduce temperatures. Hope to release in a month or two. Will be under the name of JoTo Systems.

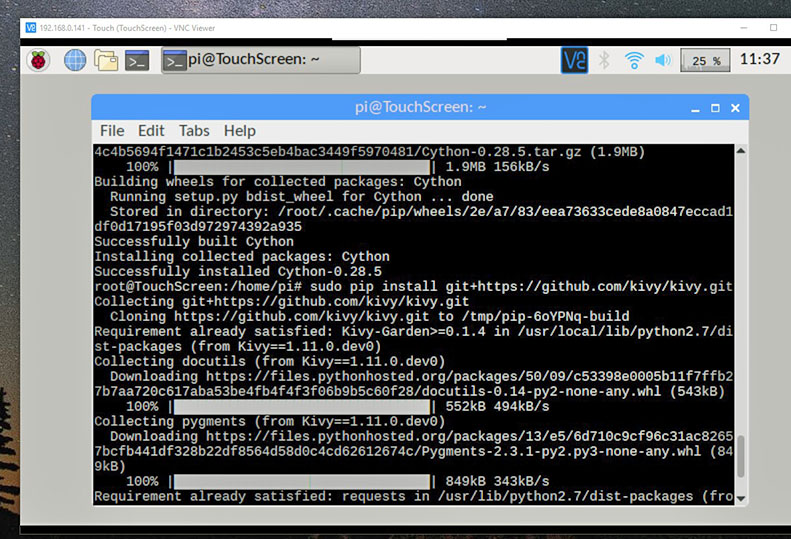

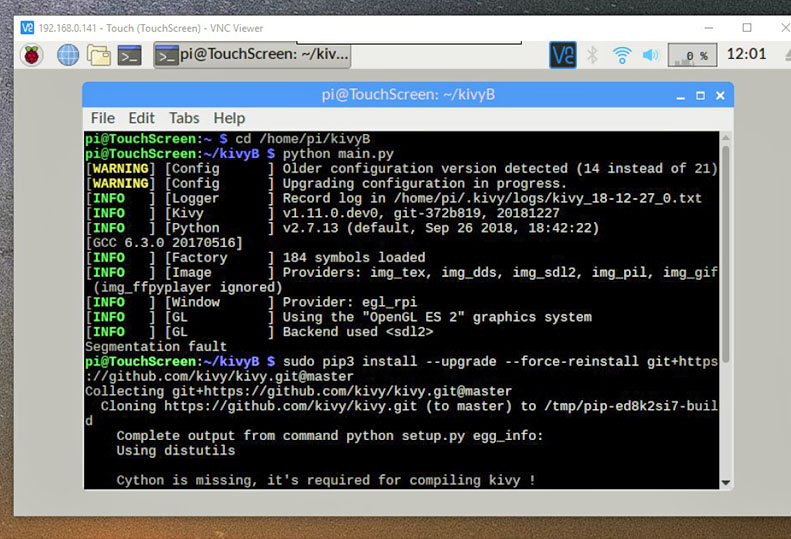

day 2 in my ‘fight’ to get kivy up and running

The more I look at all the errors the more I realize I know absolutely nothing, takes a lot of time to google

- http://www.weigu.lu/sb-computer/pitoucon/index.html

- https://stackoverflow.com/questions/46997565/proper-way-of-installation-of-kivy-1-10-with-python-3-on-raspberry-pi-3-with-7

- https://kivy.org/doc/stable/installation/installation-rpi.html

- https://kivy.org/doc/stable/api-kivy.uix.vkeyboard.html

- https://packaging.python.org/tutorials/installing-packages/

- https://www.codementor.io/kiok46/beginner-kivy-tutorial-basic-crash-course-for-apps-in-kivy-y2ubiq0gz

- https://www.youtube.com/watch?v=CYNWK2GpwgA

- https://www.youtube.com/user/sentdex/videos

* day 3 … I give up installing Kivy on RPI3 A / Jessie + hdmi touchscreen

now searching for a visual Python3 version that works

Ignoring the impact of sensor placement, solar radiation, wind eddy currents, etc. Having 2 decimal places for temperature and humidity seems unrealistic and adds clutter (noise) to the interface. What is the repeat-ability % for the sensors you are using?

@Sandgroper, totally agree. Part of this work is still in R&D and since sensor accuracy and repeatability are still part of the study I am sending one extra digit for now. Since sensors have digitising and other errors, I’m also looking at how many samples I should take and the time period between each to make up one reading.

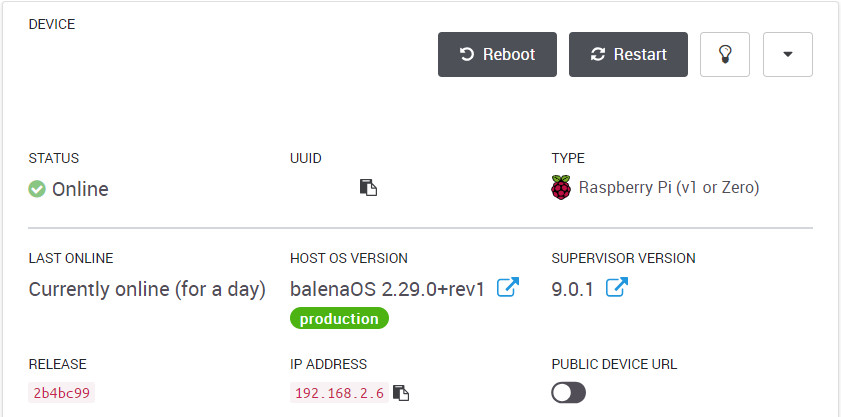

And the original @kersing spec gateway lives again. @Jeff-UK the culprit was indeed the SD card which I suspect was just worn out despite the moisture I found inside the enclosure!

There has been much talk about number of writes and such like with SD cards and this card was of unknown origin before it was put to work on the roof of my house. It is is an enclosure which should be small enough retain a bit of the RAK831’s heat in the winter but large enough to survive our modest heat in the summer. It has survived two winters (uncharacteristically cold) and 1.5 summers, one of which was pretty hot and dry so I guess just a nuisance to have to haul it out and replace.

The SD card image was one I found on my PC which was Jac Kersing’s packet forwarder and which booted no problem and allowed me to use the balenaCloud dashboard to update. One more trip to the roof and all was well and a day later, still all well…

And the offending item? When I pulled out a MicroSD card adaptor it had a second unresponsive SD card in it already. I should throw more defective stuff straight in the bin!

No name cards…use with caution from start imho! If not willing to stake name/brand rep then why should you

Glad to see you back up & running…

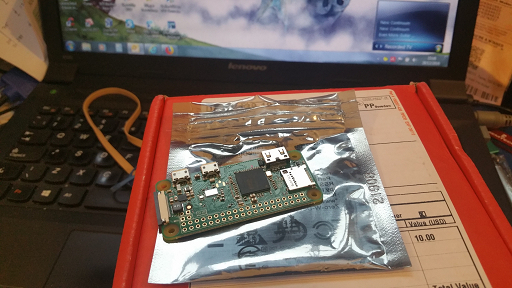

Belated Xmas pressie to myself finally arrived today - was expected ~week back! Can finally finish next RAK831 GW build

What amazes me is it was cheaper to buy this RPi0W from US vendor - even though built in a factory in UK (S.Wales) and have it shipped back than to buy from a UK/EU channel - even allowing for shipping (similar charges from UK stock vs across Atlantic)…not good for environment, but better for pocket!

Also frustrating that vendors only seem to sell 1 off’s of these versions (unless buying the ones with headers added - more expensive and dont work for the GW builds!  ) - as I prefer to build & configure gateways in small batches - 3 to 5/6 at a time for speed, efficiency and economy. Shipping costs spread over more boards would be even better value!

) - as I prefer to build & configure gateways in small batches - 3 to 5/6 at a time for speed, efficiency and economy. Shipping costs spread over more boards would be even better value!