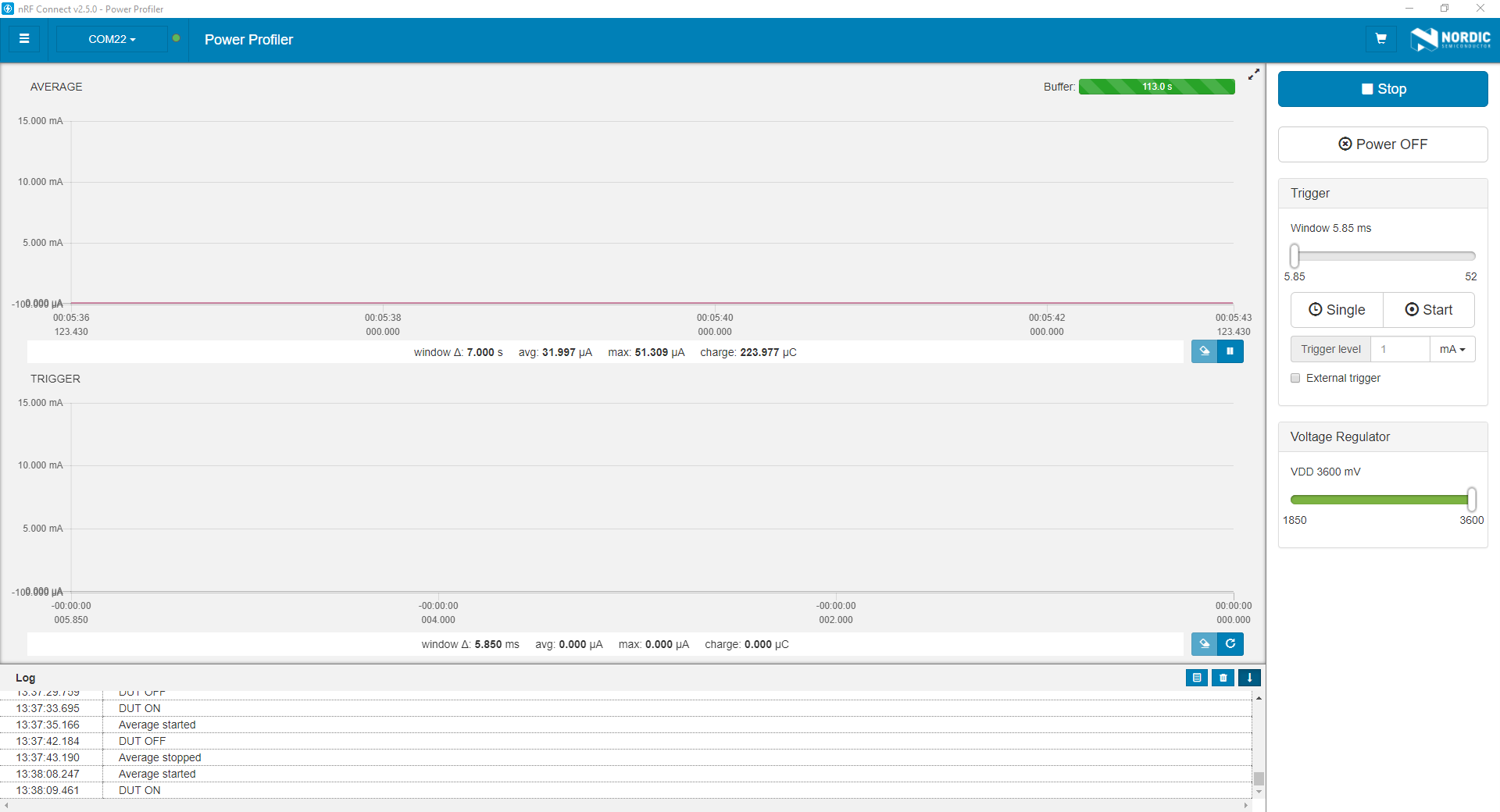

Here’s some examples of the RM186’s power consumption. The first is the RM186 essentially idling - smartbasic is running an autorun program that has periodic events (rather than sitting in interactive mode). The program closes the UART, there are no stray print lines to accidentally cause the UART to get switch back on. On this PCB, there is an efficient low drop out regulator regulating 3600mV to 3300mV (hence there will be some loss there) and additional hardware is powered off (the RM186 is controlling a mosfet to force this).

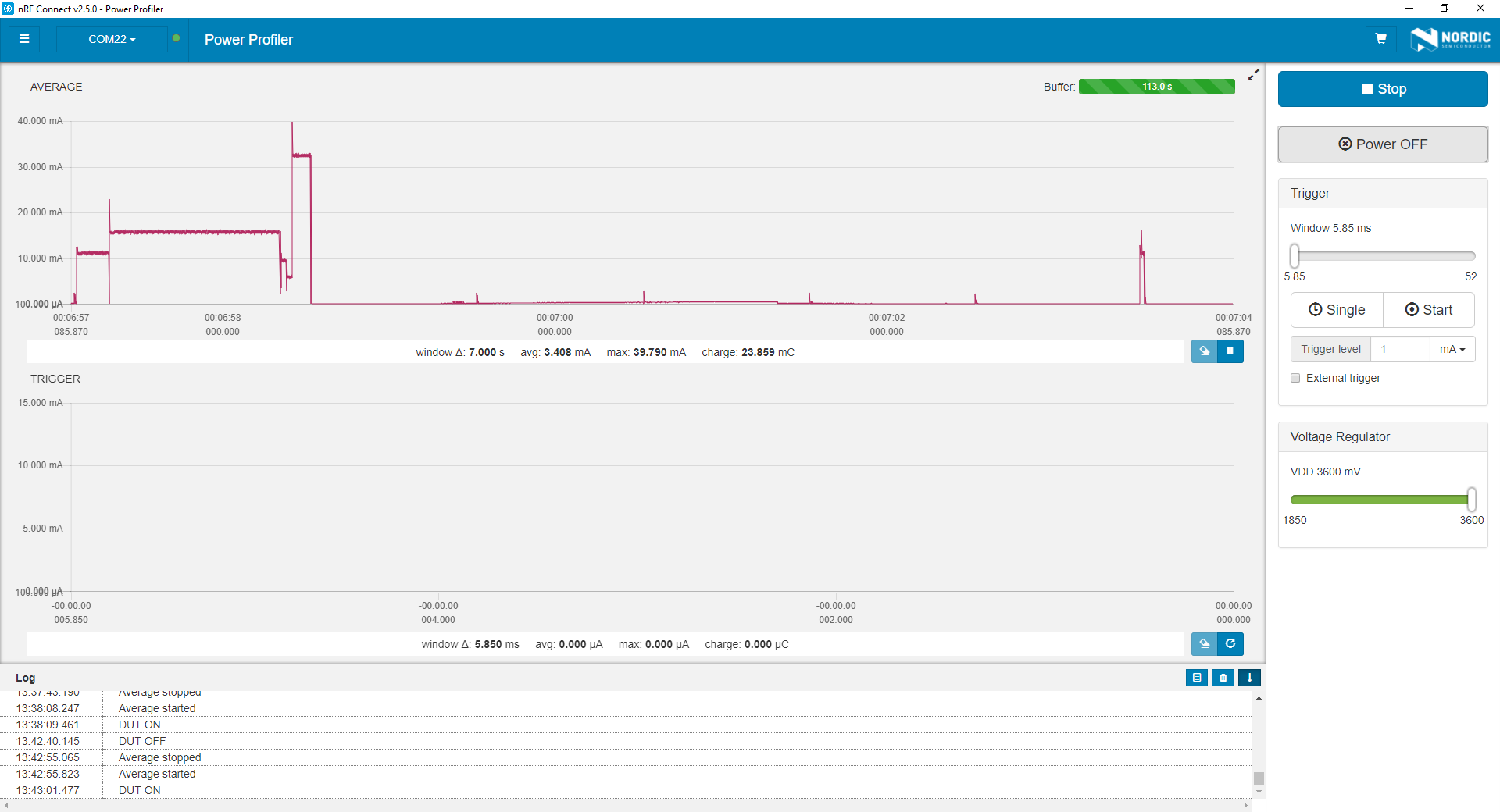

The second picture gives an example of a OTAA join request, you can see the actual transmission on the left side of the graph and then the receive window is opened a little while later.

Essentially < 100uA is more than possible, but requires you to fully use the event system, be mindful of things like your regulators and quintessence current draw, carefully control what onboard peripherals and on pcb peripherals you have.