I might have to invest in something like this for Qi charging in the field! (8000mAh - not 50000mAh - a bit optimistic me thinks!

BoRROz:did you try a hairdryer… maybe there is moisture inside

I tried, but when I take it out, same happens.

stuck on exactly 52% ?

Few percentage difference, but stuck again… Temperature and pressure are measured ok. I had before one BME280 sensor which was stuck od 100% when outside even when was hot and dry air. I use it inside now and works great. Probably it is problem with water inside.

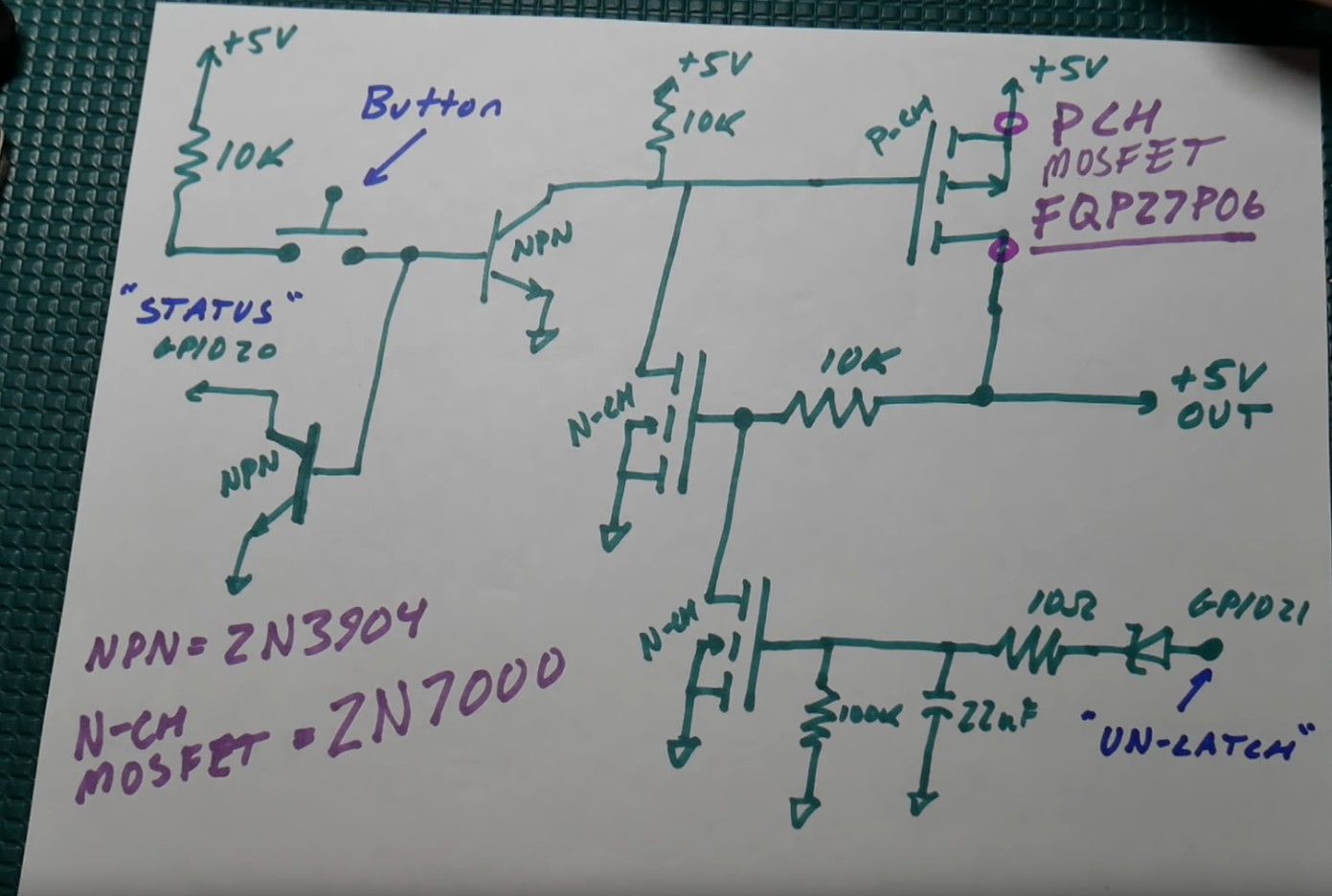

Yes I need something like that, but I want it to switch on/off the Pi + AMP with 3.7v.

Then feed it into the DC-DC to get 5v, So a soft switch for a battery operated Pi.

circuit from the video

please say that’s real

I don’t know if it’s enough earth ?

I didnt know my electrician did work for other people!?

5 additional RAK2245 gateway boards arrived today to add to the first two I have. Using the RAK2245 Stamp version for a compact gateway, just testing using a Raspi at the moment before moving to something smaller. Looking for improved receiver performance and better heat transfer in high ambient temperatures.

keep us informed Tony

Will Do. See my first modification, sweated off the ufl antenna connector and replace with SMA. PCB has pads for this. Nice!

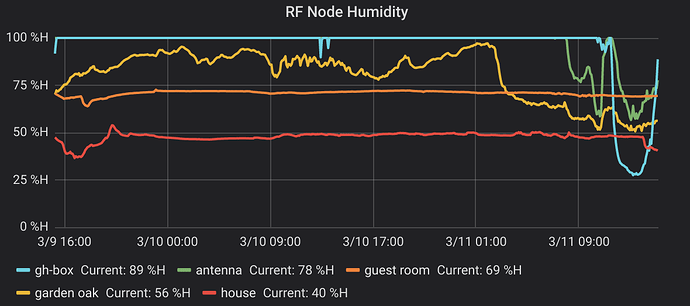

I have several bme280’s outdoors and am also wondering a bit about “the 100% phenomenon”. They’re not permanently stuck but they seem to have a hard time coming off the 100% mark when it stops raining or being foggy. For example, in the following chart (48 hours) with 2 indoor & 3 outdoor bme280’s the blue and green ones really seem stuck on 100%:

The blue one is actually in a greenhouse. The yellow is also outdoors but under a tree. It’s also often stuck at 100% and I’m surprised it didn’t go there this time.

My BME280’s are mounted in a radiation shield and soldered to a vertically positioned PCB. I wonder whether they need to be mounted with the hole facing down (i.e. under a horiz. mounted PCB)? But if it’s condensation inside the sensor I doubt that would make a difference, it’s not like a drop of water can really flow out of that tiny cavity.

From tests I’ve read the bme280 seems like the most reliable and accurate of the humidity sensors available, but I wonder whether I need to complement it with a different type when RH >90%?

@tve @slaven96 Remember moisture in the air travels without the need for air movement (eg wind). As an example, inside a room with no air movement you can have temperature differences, but moisture levels will equalise very quickly even without moving the air. As a result the BME280 sensor can be inside a heavily protected enclosure and will still measure humidity correctly. My 3D printed enclosures have a tortuous path from the outside to the sensor. I to looked at the small hole in the sensor and to confirm water droplets would not reach the sensors I performed the “spray test”. I assumed a can of spray paint emits droplets similar in size to many agricultural machines. By using Yellow Paint, I could check how far the droplets reached inside the housing.

I have a series of BME280 outside in an agricultural installation. They are rained on, sprayed by fertiliser spray machines, fogging machines etc and not had a problem.

Hi Tony!

Any photo (inside/outside) of the enclosures you use?

I have several of them. Temperature stays accurate, but hum has problems after half a year. But most stuck at 100%

And in parallel the same SHT31 works since over two years reliable…

How do you get accurate temperature measurements without air movement? Do you have lots of airflow around your 3D enclosure?

This all started as I was curious about the very small and single hole in the BME280 sensor. It only has one hole, so how does the air get in and vice-versa?

My enclosure is normally installed in a tree or the “crop of interest” but never in direct sunlight so the enclosure is at ambient air temperature and in this situation there is plenty of airflow around the outside of the enclosure. As a result the enclosure itself is at ambient temperature.

Being a LoraWan based device, I’m not sampling 1,000 times per second, more like every 20 minutes, so there is plenty of “settling time” for the sensor to adjust to a change in air temperature. My discussion about airflow was not to say the design stops all airflow but there is sufficient restriction to stop droplets of water from getting on the sensor. Its far more restricted than you might expect but I exploit the phenomena how moisture travels in air.

It’s a balance between letting in water droplets and completely stopping airflow. Maybe I should name this the Goldilocks enclosure? ![]()

some old pics related, inside the BME280

lots of problems with 100%

empty dessert packaging to the rescue, for the airflow I’ve made some holes

this ‘solution’ helped a lot (looks a bit stupid  )

)

but after some month’s I needed to use my special tools