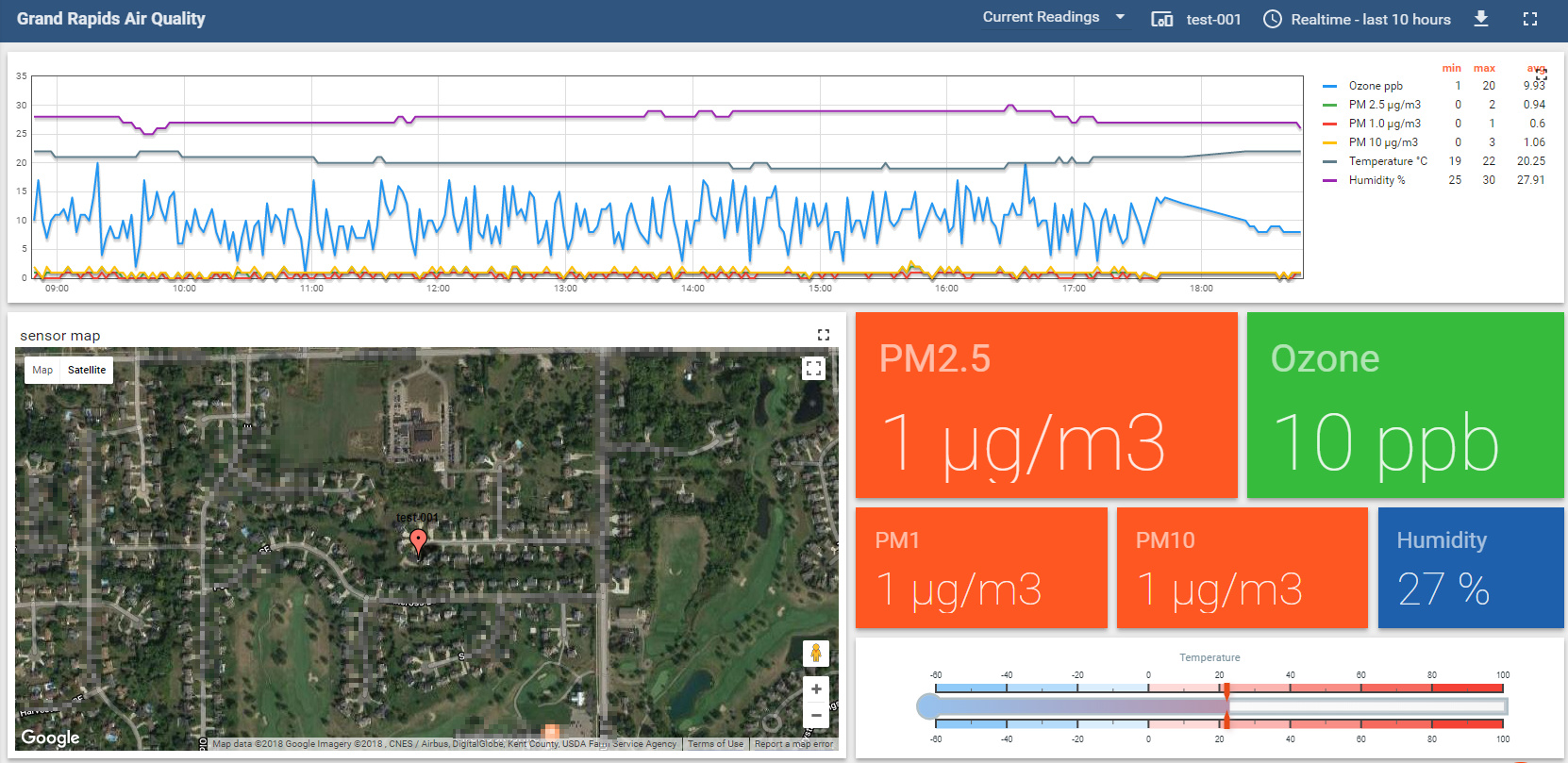

I’ve been working on an air quality monitor for the local city. The first generation units were 3D printed, stuffed into a PVC pipe, then hung on the rail next to EPA monitors to characterize sensor performance. Those are using WiFi to send data to a local LTE modem to be recorded and presented on a public website.

I’m now working on the 2nd generation units using the HelTec ESP32/LoRa boards I discovered while reading these forums. Before developing the outdoor version, I wanted to make an indoor unit that I could use for software development and demonstration.

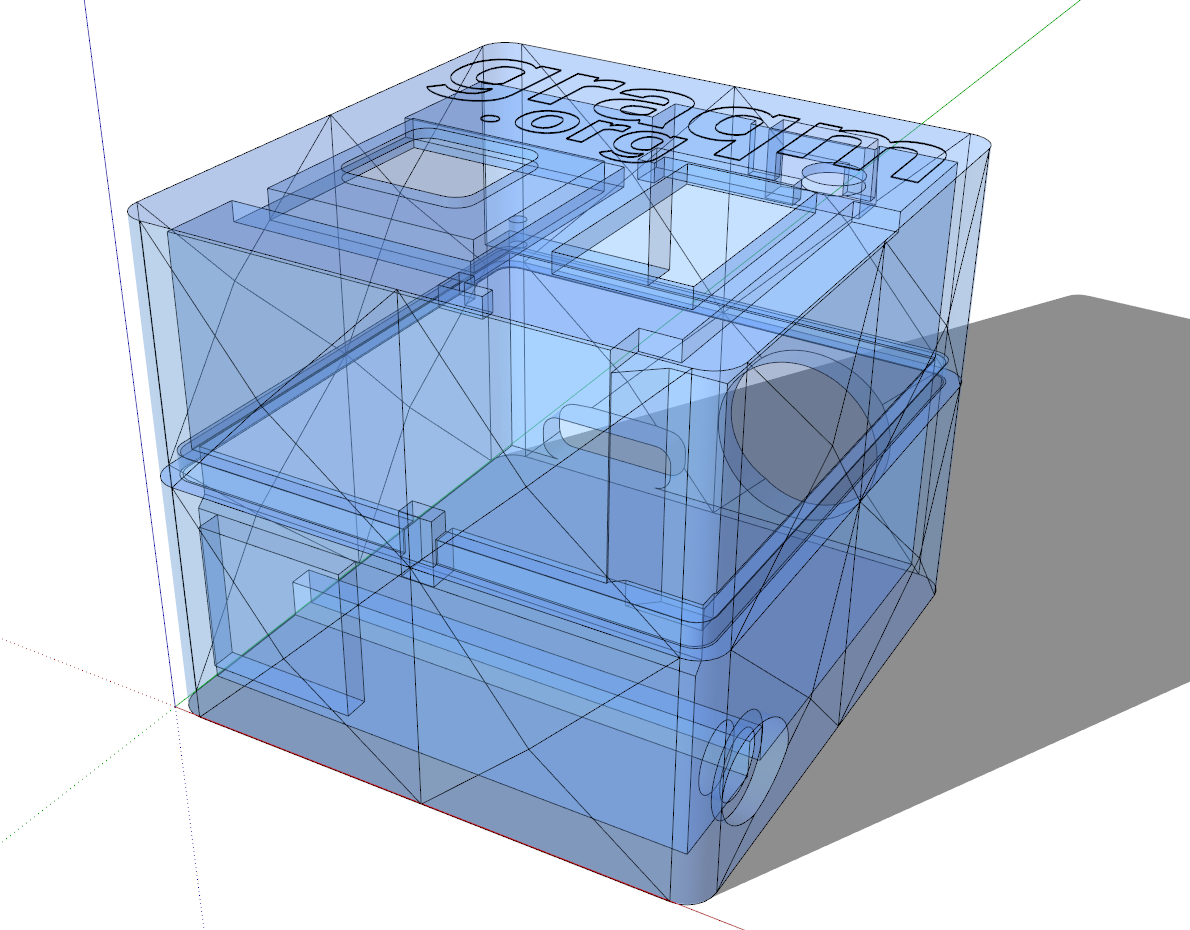

Here’s what the enclosure looks like modeled up in SketchUp:

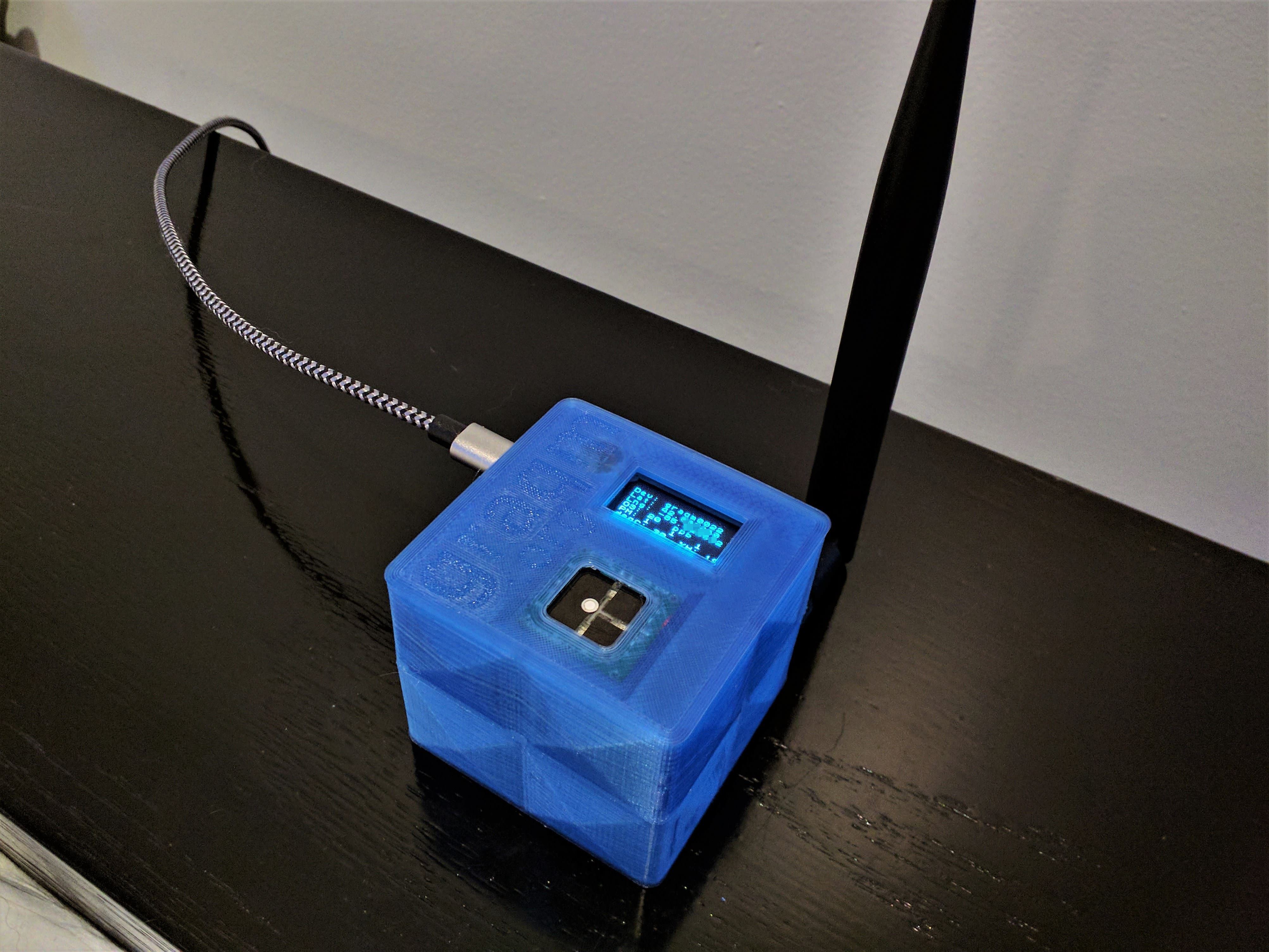

Some action shots of the assembled unit. These were printed on a Prusa Mk2 (Prusa printers are seriously top-rate, you get what you pay for here) using Atomic Sapphire Blue PETG Pro.

The unit has a PM sensor, O3 sensor (which also provides temp and humidity), along with a GPS module. This is all sent to a ThingsBoard deployment on a cheap VM in Azure for a realtime display of position and sensor data: